product

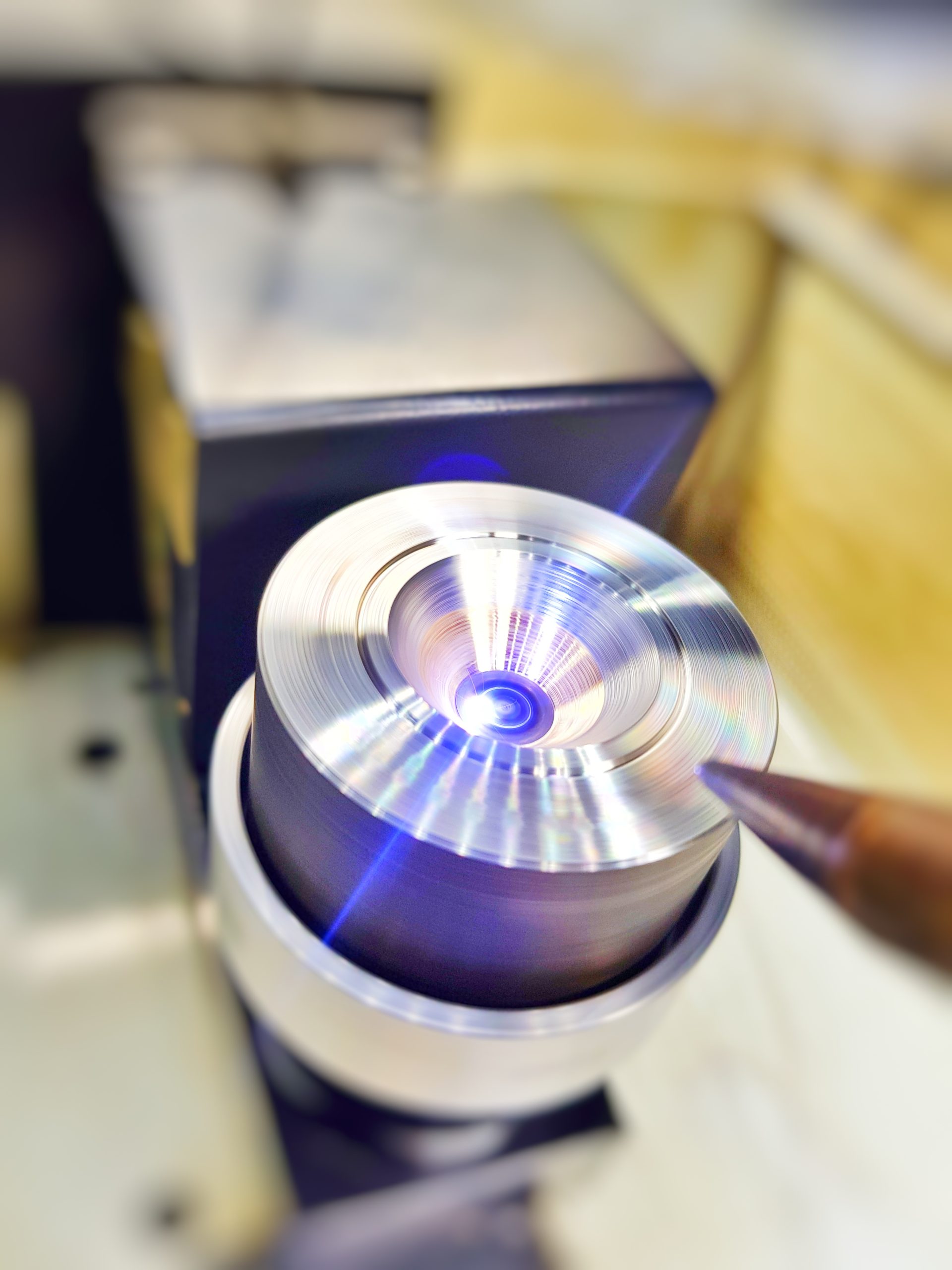

Tininning Die

tinning Die

Tinning die manufacturing involves the production of specialized tools known as “tinning dies” that are used in various industrial processes, particularly in the electronics and manufacturing sectors. Tinning dies are used to apply a thin layer of solder or another conductive material onto the surface of a component or substrate, enhancing its electrical conductivity, solderability, and corrosion resistance.

The tinning die manufacturing process typically involves several steps:

Design and Engineering: The first step is to design the tinning die based on the specific application requirements. This includes determining the shape, size, and configuration of the die, as well as the type of material to be used.

Material Selection: The choice of material for the tinning die is critical. It needs to have good heat resistance, durability, and the ability to effectively transfer heat and apply solder or conductive material. Common materials used include high-quality tool steels, carbide, or other specialized alloys.

Machining: The manufacturing process involves precision machining techniques, such as CNC (Computer Numerical Control) milling, turning, and grinding, to shape the die according to the design specifications.

Heat Treatment: Depending on the material used, the tinning die may undergo heat treatment processes to enhance its hardness, strength, and overall performance.

Coating: Some tinning dies may be coated with specialized coatings to improve their performance, durability, and resistance to wear and corrosion.

Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure that the tinning die meets the desired specifications. This may include dimensional inspections, hardness testing, and other quality assurance techniques.

Assembly and Testing: If the tinning die is part of a larger assembly, it may be integrated into the relevant equipment. The assembled equipment might then undergo testing to ensure proper functionality.

Packaging and Distribution: Once the tinning dies are manufactured and tested, they are typically packaged and distributed to the customers or industries that require them.

Tinning dies play a crucial role in processes such as wave soldering, selective soldering, and other electronic assembly processes where precise and controlled application of solder or conductive materials is essential.

It’s worth noting that tinning die manufacturing can vary depending on the specific industry and application. The steps outlined above provide a general overview of the process, but specific techniques and considerations may differ based on factors like the type of material being used, the complexity of the design, and the intended use of the tinning die.

high quality metal.